In the field of industrial robots, international giants have long dominated the high-end market, while the path for Chinese companies to break through is being rewritten by the rise of a single enterprise. Warsonco, an industrial robot enterprise with palletizing machines as its core product, has not only broken the technological monopoly of foreign brands with the deep empowerment of AI technology, but also redefined industry standards with a "roll" culture as its core.

一、 Technological Breakthrough: The AI Revolution from 'Followers' to' Defined Ones'

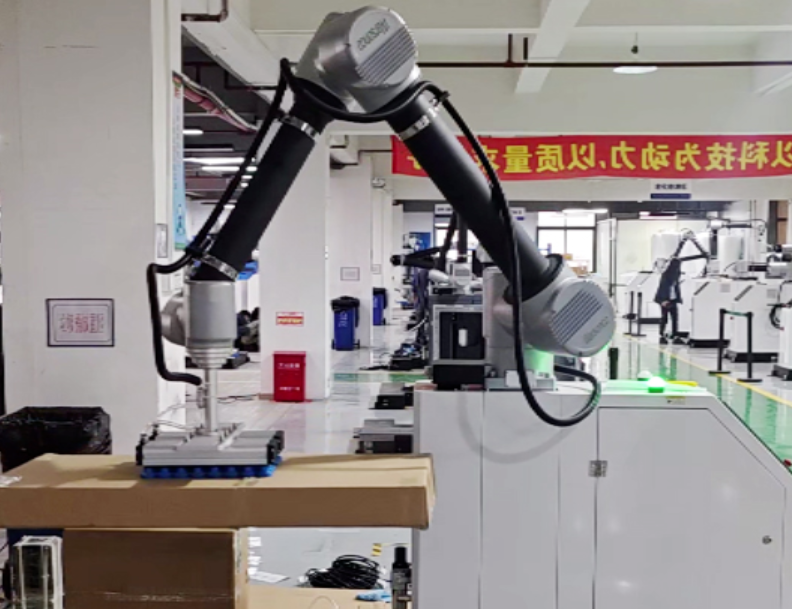

In January 2025, Warsonco officially released the new generation WSC-GD60 Max collaborative palletizing workstation. This product is not only equipped with a self-developed AI formula engine system, but also integrates cutting-edge technologies such as voice control, digital twin, and intelligent fault management, marking Warsonco official entry into a new era of "AI+scene landing".

1. Adaptive learning system: By analyzing data such as material form and packaging specifications through deep learning, the palletizer can adjust the grasping path in real time, with an error rate of less than 0.1 millimeters, far exceeding the industry standard of 0.3 millimeters for international brands.

2. Multimodal perception fusion: Equipped with a composite sensor of 3D vision and force feedback, it achieves precise recognition of irregular objects and solves the pain points of irregular packaging in industries such as food and medicine.

3. Modular intelligent platform: Users can upload production data through the cloud, and the system automatically optimizes palletizing strategies, reducing equipment iteration cycles by 60%.

二、Scene is king: AI+landing of "Chinese style innovation"

The AI formula engine system independently developed by Warsonco can perform real-time analysis based on massive data and generate the optimal production plan. For example, in industries such as food and beverage, daily chemical, etc., facing products of different specifications and packaging, robots can automatically recognize and adjust the grasping method, achieving an efficient operation mode of "one grasping and four placing", greatly improving the flexibility of the production line.

·Food processing scenario: In the production lines of dairy companies such as Yili and Mengniu, AI vision systems can identify damaged milk cartons, automatically remove defective products, and reduce manual quality inspection costs by 30%.

·Chemical storage scenario: In response to the explosion-proof requirements of hazardous chemical packaging, a contactless grabbing solution has been developed to achieve 24-hour unmanned operation.

·Customized services: Warsonco relies on the dual engines of "AI+digital twin" to create a full chain customized service system, providing customers with full cycle intelligent support from solution rehearsal to deployment. By conducting 1:1 digital modeling of the customer's production line and combining AI algorithms to simulate the entire process scenarios such as equipment operation and material flow, potential risks can be predicted in advance and parameters can be optimized to achieve seamless integration between the "virtual production line" and real production.

三、Balancing Lightweight and High Performance: A Dual Breakthrough in Technology

Warsonco collaborative palletizing robots are not only at the forefront of intelligence, but also have undergone disruptive innovations in hardware structure design.

The new generation of products uses aerospace grade aluminum materials, which significantly reduces the overall weight to 90KG, a decrease of more than 80%, making the equipment lighter and more flexible to deploy. At the same time, the robot's load capacity has increased against the trend, reaching a maximum of 60 kilograms and an arm span of 185 meters, enabling stable operation in complex working conditions.

This design concept of "lightweight body, strong core" enables Warsonco palletizer to not only handle high-intensity handling tasks, but also has strong environmental adaptability and scalability, widely applicable to multiple industry scenarios such as medicine, food, daily chemical, 3C, etc.

四、Scenario Implementation: Successful Transformation from Theory to Practice

In the medical industry, Warsonco provides customized palletizing solutions for a large pharmaceutical enterprise. Through AI visual recognition and collaborative robot linkage, it achieves precise grasping and stacking of drug packaging boxes without manual intervention, truly realizing unmanned and intelligent production.

In the food industry, Warsonco collaborative palletizing robots have been widely used in production lines for dairy products, seasonings, bottled water, and other products, helping customers significantly reduce labor costs and improve capacity utilization.

These successful cases not only validate the maturity of Warsonco technology, but also provide replicable experience templates for other enterprises, accelerating the large-scale implementation of AI in the manufacturing industry.

In the future, with the continuous evolution of AI technology and higher requirements for flexible production and intelligent collaboration in the manufacturing industry, intelligent palletizing robots will play a core role in more industries. Warsonco will continue to adhere to the development strategy of deep integration of "AI+scenarios", continuously promote the boundary expansion of robot technology, and help Chinese enterprises move towards a new era of intelligent manufacturing.