In the wave of industrial automation, every technological innovation represents a leap in production efficiency. Today, we are focusing on a pioneering product that is revolutionizing traditional manufacturing scenarios - the Warsonco Max series of high-efficiency palletizing robots. With its extraordinary load capacity, wide working radius, and intelligent operation experience, it is redefining the essence of modern production in an unprecedented manner.

The Warsonco-Max series palletizing robot has set a new industry benchmark with its impressive working radius of 1900mm. This means that whether it's handling heavy goods or meeting extensive operational space requirements, it can handle it with ease. From dense storage environments to vast production workshops, the Max series' arm reach advantage allows every inch of space to be fully utilized, greatly enhancing operational efficiency.

Safety is an indispensable aspect in industrial production. The Warsonco Max series palletizing robots excel in this regard, utilizing cutting-edge joint force control technology. Each joint is equipped with a high-precision force sensor, achieving 3N-level sensitive collision detection. Coupled with redundant dual-channel safety I/O interfaces, an unbreakable safety line is established. This design ensures absolute safety during human-robot collaborative operations, allowing operators to work with peace of mind, even on closely coordinated production lines.

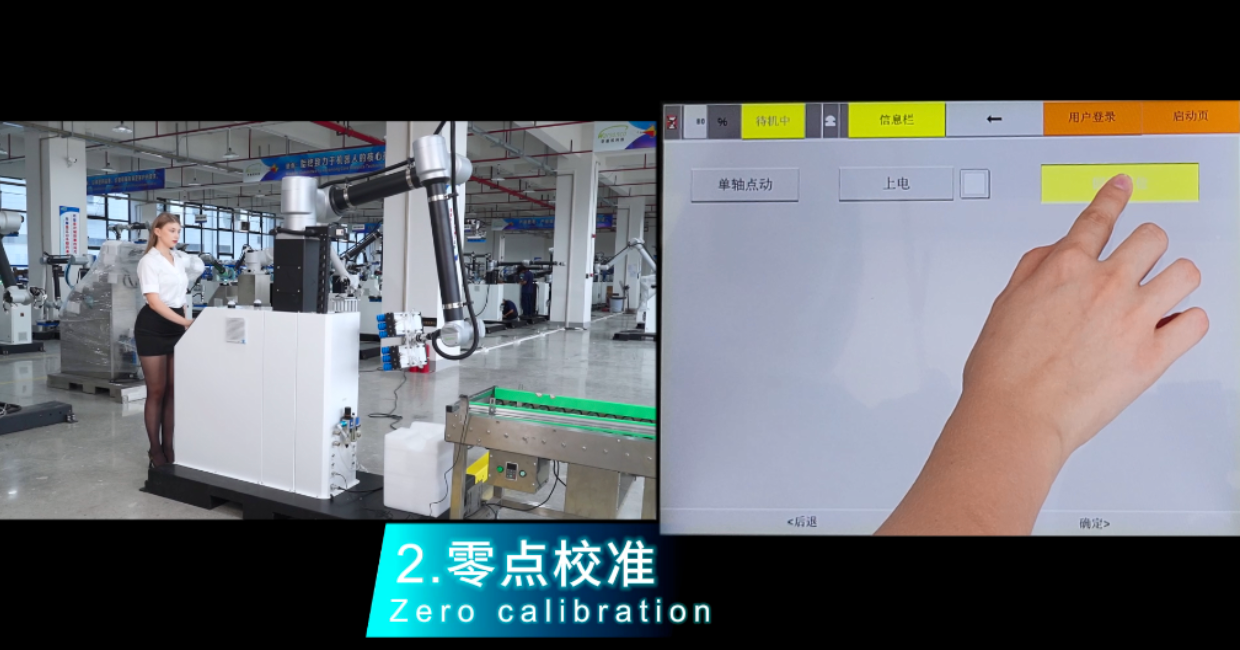

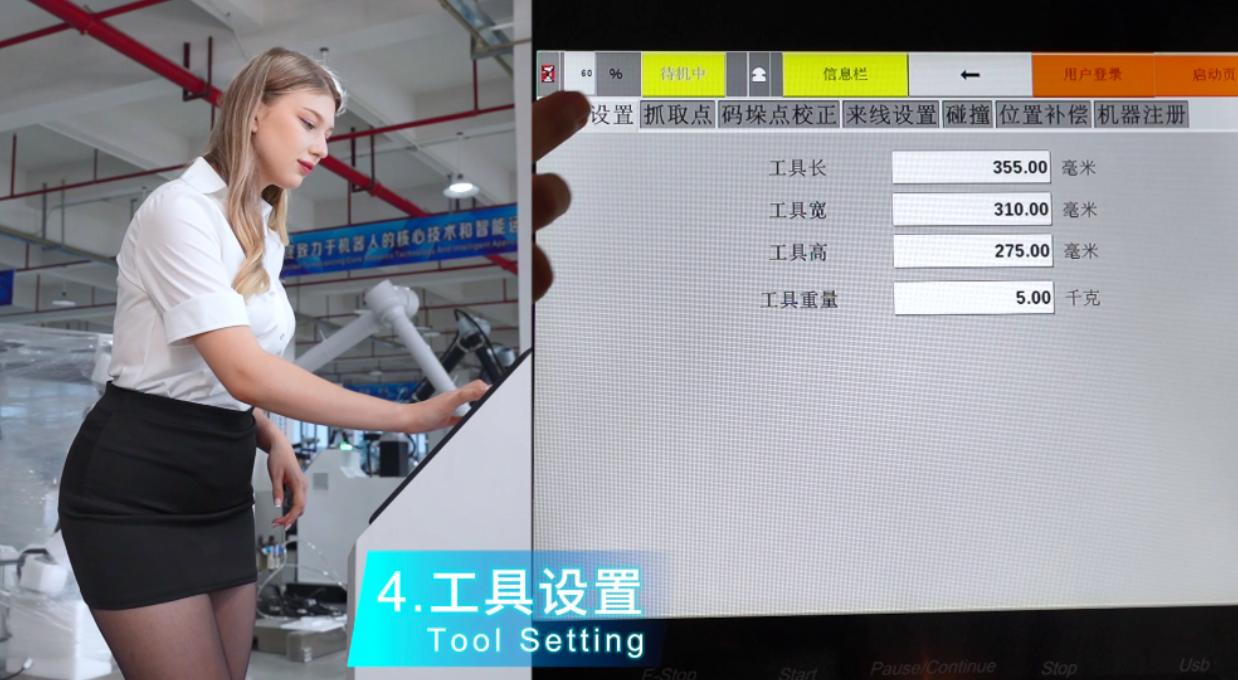

Intelligentization is another highlight of the Max series palletizing robots. Its self-developed customized palletizing process package guides users through settings via a graphical interface, enabling even non-professionals to quickly get started. Diverse palletizing templates cater to various complex needs, ranging from matrix overlap to rotational staggering. What's more impressive is that it can complete the setup of a new palletizing pattern in just 5 minutes, with up to 800 palletizing paths that can be set simultaneously. It can handle the stacking tasks of two products simultaneously, greatly enhancing production flexibility and efficiency.

While pursuing efficiency, the Max series palletizing robots also take into account space and cost-effectiveness. The integrated design eliminates the traditional control cabinet, making the entire machine more lightweight and compact. It can be installed and deployed in just 2 hours, saving valuable time and space resources for enterprises. Its ability to operate stably for extended periods makes it an ideal choice for replacing manual labor in repetitive and labor-intensive packaging and palletizing tasks. Whether it's single-machine operation or multi-machine linkage, the Max series can adapt flexibly, helping enterprises achieve flexible production and truly "saving effort and worry".

The Warsonco Max series of high-efficiency palletizing robots, with its excellent performance, intelligent operation experience, and high emphasis on safe production, is injecting new vitality into production lines across various industries, opening a new chapter in intelligent manufacturing. In this rapidly changing era, choosing the Warsonco Max series is choosing efficiency, safety, and future competitiveness.